Crusher Chutes

Mining Chutes Novelty Steel

2 天之前 — In crushing plant design, a chute plays a crucial role as a steeply inclined trough facilitating the smooth transfer of materials onto a conveyor There are two primary types 2016年2月24日 — plug chutes, reduce surge capacity, and decrease the live storage capacity of bins and silos To address this problem, chutes must be easily accessible for cleanup, Crushing Plant Design and Layout Considerations 911

.jpg)

4: The feeding chute of the HPGR crusher in gray

In this work the HPGR crusher will be modeled with its internal dynamics, coupled with interconnected mod95 ules that connect material properties and operational settings to the output 2021年7月1日 — A better crusher control, 36% increase in the crusher throughput and finer and narrower product size distribution were among the main outcomes of the new feed DEMbased design of feed chute to improve performance

.jpg)

Feed Chute

The features of the Feed Chute address the issues with feed chutes that often disrupt our customer’s business With our design choices, we can reduce downtime, improve safety and simplify access4 天之前 — Chutes are in use in almost every bulk solids handling plant Although everybody knows them, they are mostly overlooked, except for those cases where they cause extra Chute Design Essentials – How to Design and Implement Chutes

Wear liner packages XLOK

2021年7月20日 — Traditionally crusher discharge chutes, sometimes called vaults or octagonals, are a challenge to protect with wear liners and can be even more difficult to Blocked chute detection in a Mining process application is crucial to the operational performance of the site Hours lost to downtime caused by a blockage in a conveyor transfer chute can take hours to clear, which in Conveyor Transfer Chute Level Monitoring

.jpg)

Crushing Wheel Create Wiki Fandom

3 天之前 — Crushing Wheels are the more advanced version of the Millstone It applies Crushing recipes to any items inserted from the direction they are spinning away from 1) First, arrange the crafter as follows Note that SAG Mill Feed Chutes Stockpile Reclaim Chute Liners Makuri MAKHard Bimetallic Liners MAKBund Liners Chute Liner Mounting Options MAKBloks in Chutes High Performance Parts Specialists News News Events Our news items are regularly updated, so check back often All News January 07th, 2022Chute Liners Makuri Group

Chutes KVK Hydra Klov

2024年2月26日 — Choose the chutes you want to compare by clicking on the photos below In the comparison you will find a video that explains the hoof trimming crush step by step and shows it in practice 10001; 8001 2024年7月19日 — Fixed Plant Liners for Transfer Chutes/ Crusher Liners/ Sizing Screens The smooth overlay plate was manufactured using advanced fusion bond submerged arc welding technology to apply a highly abrasive resistant chromium carbide on to a steel substrate producing consistent chemistry and micro structure (austenitic) with smooth Fixed Plant Liners for Transfer Chutes/ Crusher Liners/ Sizing Screens

.jpg)

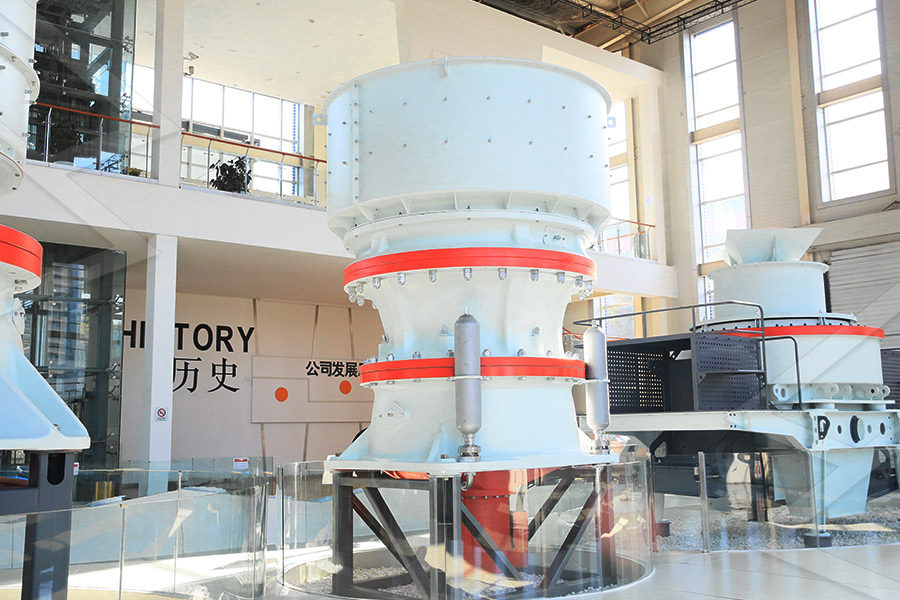

Cone Crusher Spares Kenmore

Home Services Cone Crusher Spares Cone Crusher Spares Kenmore Group of companies offer a wide range of liners and spares for most common cone crushers ranging from 2′ , 3′, 4′, 4 1/4′, 5 1/2′ and 7′ as well as an engineering service to design and supply liners or spares for your specific crusher needs []2024年5月28日 — Bid Description: 20/FTC001/MAY’24/TS RPF FOR SUPPLY, FABRICATE AND INSTALL NEW CHUTES IN SECONDARY WEST CRUSHER PLANT Place where goods, works or services are required: FOSKOR Phalaborwa Mine, 27 Selati Rd Phalaborwa Phalaborwa 1389 Opening Date: Tuesday, 28 May 2024 Closing Date: 20/FTC001/MAY’24/TS RPF FOR SUPPLY, FABRICATE AND INSTALL NEW CHUTES

Crusher Parts The Makuri Group

Crusher Parts Crushers We understand crushers, chutes and screens and their wear related issues better than most Contact us to see how we can optimise your process plant front end to improve overall plant throughput, maximise asset 2016年4月23日 — As in the case of the main dump hopper, many crusher chutes have electric heating elements to prevent the oil sands from sticking Although crusher capacities can vary between the operators, most crushers have a nominal (steadystate) capacity of between 8,000 to 10,000 tonnes per hour The largest crushers used in the oil sands OPPDry: Materials Handling Facilities Oil Sands Magazine

Noise and Vibration Control in Crusher Plant Activities to Enhance

2019年4月8日 — Six crusher plant sites were selected based on their varying production capacity for the study Accordingly, selected sites were visited to carry out area noise and wholebody vibration surveysREXLINE™ – Laminated Wear Blocks are unique wear resistant materials in that they combine very high wear resistant qualities of white iron (ASTM A532 15/3CrMo, 700BHN – 63HRc) with a weldable high impact toughness mild steel through a metallurgical bond to create a product that has a exceptional resistance to impact and abrasion NiHard Rexline™ Engineering Cco Nihard Wear Liners RexLine

.jpg)

Wear linings for crusher discharge vaults

Traditional crusher discharge chutes, vaults and octagonals are a challenge to protect with wear liners and can be even more difficult to maintain and repair They are often surrounded by structural concrete, which prevents 6 天之前 — Telescopic Chute: Loading Chutes Spouts MNSTACKER is a Chinese manufacturer of telescopic spouts for loading bulk materials A telescopic loading spout, also named as telescopic loading chute or loading belows, is an efficient device for loading bulk materials into trucks, trains, and ships with integrated dust remover and automatic Telescopic Chute: Loading Chutes Spouts MNSTACKER

Chute Create Wiki Fandom

5 天之前 — Chutes transport items vertically, similarly to Mechanical Belts Chutes can insert or extract from inventories above or below them Connected chutes will pass items along, similarly to a Mechanical Belt, EPC For New Crusher Feeders, Transfer Chutes Receiving Hoppers Situation KCPL LaCygne was experiencing severe spillage and dust problems due to feeders at endoflife in Units 1 and 2 of their secondary crusher house As a result, KCPL engaged Benetech to assess the situation and come up with solution/s that would:Crusher Feeders, Transfer Chutes Hoppers Benetech, Inc

roll crusher feed and discharge chutes instructions 2020md

showing spiral crushing and feeding rollsOne of theOne installation pro 1eatad between theia# Adjustable gates oa the discharge side of the rolls canCrusher Discharge Chute Drawing Jaw Crusher,ConeRoll crusher feed and discharge chutes lyrics youtube crusher users to replace worn parts or repair damaged ponents in the case of roll crushers these Many industrial facilities, mines and power stations rely too much on dust suppression and extraction systems, when the real answer is to improve the flow of material through welldesigned chutes This is the opinion of Weba Chute Systems technical director Alwin Nienaber, based on decades of experience in this field His view is that 50% []Chutes Liners Archives Bulk Handling

.jpg)

Conveyor Transfer Chutes Engineered Transfer Points ASGCO

The performance of conveyor transfer chutes is an essential part of the productivity of conveyor belt systems in the bulk solids industry Engineered Transfer Points (conveyor Transfer Points) design fabrication and installations utilizing ASGCO®’s 3DEM™ (Discrete Element Methods) 3d Scanning chute analysis program is a revolutionary way to handle Stefmet Technologies have the capacity to design and fabricate chutes and launders to the client’s specifications as well as offer various wear liner options to optimize the material flow and wear life of the chutes and launders The Chute and launder wear lining options include: DuratileAlumina Ceramic tiles from 6mm thick to 50mm thick []Chute and Launders Stefmet

.jpg)

Case Study Reclaim chute liners The Makuri Group

2020年8月21日 — a primary crusher Each chute contains over one thousand individual liners and is normally buried under thousands of tonnes of rock The logistics involved in clearing this volume of material to access the stockpile are immense and production losses mount quickly, so a longlife solution was requested The initial design required the chute to2021年7月1日 — The effect of feed chute design on tertiary cone crusher performance at the Sarcheshmeh copper complex was studied by an inhouse developed DEM software called KMPC DEM © To simulate the overall crushing circuit, the multigeometry procedure by improving the routines of object files importing into the simulation environment was DEMbased design of feed chute to improve performance

.jpg)

3 Types Of Discharge Adjustment Devices For Cone Crushers ZENITH Crusher

2021年6月15日 — Cone crusher is one of the mainstream crushing equipment in mining industry It is mainly used for medium or fine crushing for various kinds of raw materials The output size of cone crusher is determined by the distance between mantle and concave But many people don’t know much about the discharge adjustment dvice of cone crusherLandscaping Chutes Ideal for: Light, flexible, and safe; Quiet during use; Equipped with safe and strong cable linking hardwarePremier Equipment Chute Systems

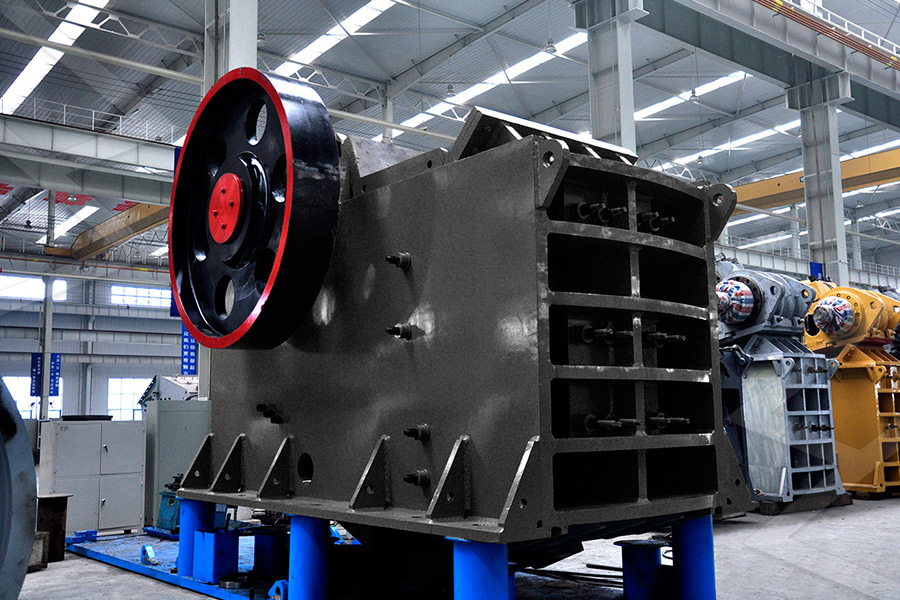

Types of Crushers Explained: Everything You Need to Know

2024年4月19日 — This crusher has hammers or blow bars that are swung at high velocity to break apart the feed material via impact forces This is not like squeezing type of crushers that use compressive forces to crush the material between two surfaces, for example, jaw and cone crushers Cone crushers with revolving cones are recognized for their capability A spring cone crusher is a compressiontype crusher typically used in the secondary or tertiary stage of the crushing process It utilizes a spring mechanism to provide overload protection Enhancing Efficiency in Mineral Processing: The Role of Spiral Chutes

.jpg)

Practical considerations on improved feeding

2016年1月12日 — Cone Crusher Function zA cone crusher has an annular crushing chamber zThe CSS runs around the chamber so the action is basically rotational zRaw material enters the chamber on the OSS and is crushed one hlf lti lt bthCSShalf revolution later by the CSS zThis cyyp pcle takes place in most cone crushers 5 to 6 times per second2 天之前 — Here are key considerations and principles in the design of chutes: 2 Chute Functionality Chutes are positioned between feeders and conveyors or between two conveyors Commonly of rectangular crosssection, chutes can also be circular or elliptical Unlike conveyors, chutes do not rely on power for operation, leading to lower Mining Chutes Novelty Steel

.jpg)

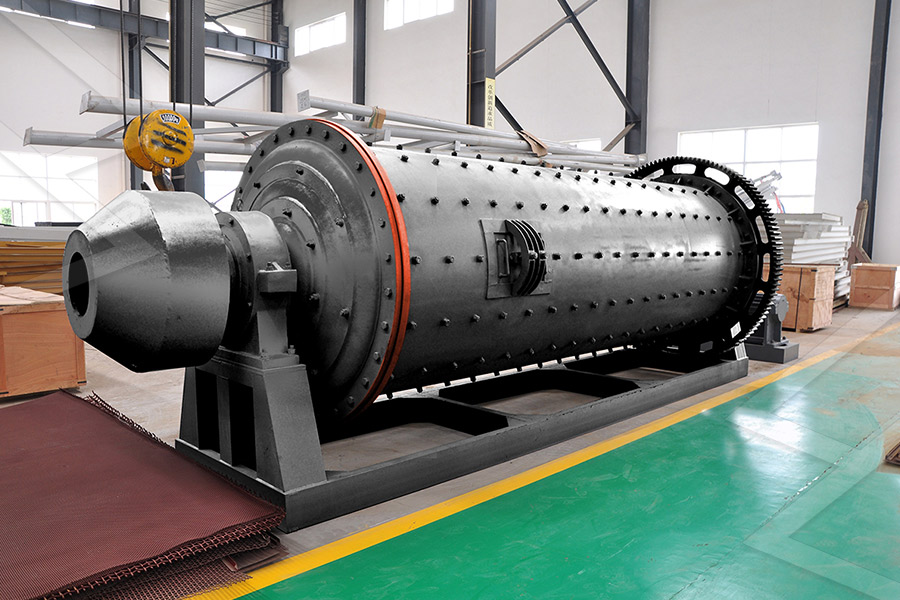

MILL FEED CHUTES Ebco Mining

MILL FEED CHUTES Ebco Mining is a worldwide supplier of Mill Feed Chute to the grinding systems industry Our unique combination of practical experience, technical knowhow, and advanced design tools has positioned us as leaders in the field We have manufactured for all the major OEM’s and supplied equivalent to OEM directly to the industry Peninsula Crusher Works can design/build chutes and diverter boxes of any size or material grade Custom built to for easy field maintenance and liner changes Our team will work with you through the entire process to ensure you getting Peninsula Crusher Works

.jpg)

Ore mine uses air cannons to unclog chutes Mineral

Although the solutions reduced clogging slightly, labor was still needed to fully evacuate the material from the chutes Compressed air usage “We realized that the air lance solution was only temporary, but was effective in moving material,” said Jason Haynes, Territory Manager for Martin Engineering2024年7月19日 — Kit (Basic Chutes) Constructing Options Chute (Straight) , Chute (Corner) , Chute (Window) , Chute (Junction) , Chute Flip Flop Splitter , Chute Valve , Chute Overflow , Chute Inlet , Chute OutletBasic Chutes Unofficial Stationeers Wiki

Numerical analysis of a protective coating for mining

2024年5月18日 — The selection of materials for the protective coating of a crusher’s feed chute significantly influences the mean time between failures (MTBF) and operational costs associated with the mass production of sulfuric acid at MMG/Kinsevere Neglecting the condition of the protective coating can pose a serious challenge to production efficiency 2019年7月22日 — COROCARB fOR extReme WeAR PROteCtION CHUTES General CharaCteristiCs APPLICATIONS FOR MINING Drilling machine Drag line excavator DISCS HAMMERS GYRATORY CRUSHER CONES BUCKET EDGE SIEVES Corodur Fülldraht has been an industry leader in the area of wear protection for 35 yearsCOROCARB APPLICATIONS fOR extReme FOR MINING

Products Gallery — Peninsula Crusher Works

Peninsula Crusher Works can design/build chutes and diverter boxes of any size or material grade Custom built to for easy field maintenance and liner changes Our team will work with you through the entire process to 2019年5月21日 — A roller crusher discharge chute on a mine in Mpumalanga “It is increasingly recognised that chutes are not just standard items of platework, but are vital facilitators of smooth plant operations,” states Baller “Like every other aspect of plant technology, they require focused technical design that creates a fitforpurpose solution Engineered Weba chutes keep plant circuits efficient Crown

More Weba chutes for expanding Zimbabwe mine

2023年2月6日 — The expansion of an underground crusher station at a platinum mine in Zimbabwe has required South Africabased Weba Chute Systems to provide 10 more of its custom engineered transfer chutes Overseeing the contract for Weba Chute Systems is project manager Ted Cruikshank, who explains that the design, manufacture and delivery 2017年3月15日 — Primary crusher crash boxes, conveyors, transfer lines, inlet/outlet chutes and inlet hoppers can all be prone to blocking, bridging or jamming, resulting in severe site problems These include: Extended and expensive down times ; Therefore reliable, early detection of imminent blockages in chutes before they reach a critical level is of Overcoming the challenges of blocked chute detection in

4 500 chute installations Bulk Handling

2019年7月9日 — Transfer chutes and systems are engineered for each specific customer application, taking factors such as belt width, belt speed, material sizes, shape and throughput into account Weba Chute Systems adopts a streamlined and scientific approach to the dynamics of bulk materials handling at transfer points, providing the industry with a The conventional CIL plant has a twostage crushing circuit consisting of a single toggle overhead eccentric swing jaw crusher, HP6 secondary crusher and double deck screen, followed by a SAG and Ball milling circuit the gold mine’s Maintenance Superintendent knew he needed to increase the wear life of material handling chutesWA Gold Mine 3x Crusher Chute Wear Plate Life Cutting

Cone Crusher Diagram: Simplified Guide JXSC

2024年3月19日 — A cone crusher is a super important machine used in mining and construction It’s designed to break down big rocks, ores, and other stuff into smaller pieces that are easier to handle The machine gets its name from its conelike shape, which has a fixed outer cone called the bowl liner and a moving inner cone known as the mantle 4 天之前 — 2 Spiral chutes application in copper Processing Applying spiral chutes in copper processing plants has revolutionized how raw materials are separated and processed Using gravity and centrifugal force, the spiral chute effectively separates the copper ore from the gangue minerals, resulting in an efficient and costeffective extraction processImproving Mineral Processing Efficiency With Spiral Chutes

.jpg)

Crushing Wheel Create Wiki Fandom

3 天之前 — Crushing Wheels are the more advanced version of the Millstone It applies Crushing recipes to any items inserted from the direction they are spinning away from 1) First, arrange the crafter as follows Note that SAG Mill Feed Chutes Stockpile Reclaim Chute Liners Makuri MAKHard Bimetallic Liners MAKBund Liners Chute Liner Mounting Options MAKBloks in Chutes High Performance Parts Specialists News News Events Our news items are regularly updated, so check back often All News January 07th, 2022Chute Liners Makuri Group

Chutes KVK Hydra Klov

2024年2月26日 — Choose the chutes you want to compare by clicking on the photos below In the comparison you will find a video that explains the hoof trimming crush step by step and shows it in practice 10001; 8001 2024年7月19日 — Fixed Plant Liners for Transfer Chutes/ Crusher Liners/ Sizing Screens The smooth overlay plate was manufactured using advanced fusion bond submerged arc welding technology to apply a highly abrasive resistant chromium carbide on to a steel substrate producing consistent chemistry and micro structure (austenitic) with smooth Fixed Plant Liners for Transfer Chutes/ Crusher Liners/ Sizing Screens

.jpg)

Cone Crusher Spares Kenmore

Home Services Cone Crusher Spares Cone Crusher Spares Kenmore Group of companies offer a wide range of liners and spares for most common cone crushers ranging from 2′ , 3′, 4′, 4 1/4′, 5 1/2′ and 7′ as well as an engineering service to design and supply liners or spares for your specific crusher needs []2024年5月28日 — Bid Description: 20/FTC001/MAY’24/TS RPF FOR SUPPLY, FABRICATE AND INSTALL NEW CHUTES IN SECONDARY WEST CRUSHER PLANT Place where goods, works or services are required: FOSKOR Phalaborwa Mine, 27 Selati Rd Phalaborwa Phalaborwa 1389 Opening Date: Tuesday, 28 May 2024 Closing Date: 20/FTC001/MAY’24/TS RPF FOR SUPPLY, FABRICATE AND INSTALL NEW CHUTES

Crusher Parts The Makuri Group

Crusher Parts Crushers We understand crushers, chutes and screens and their wear related issues better than most Contact us to see how we can optimise your process plant front end to improve overall plant throughput, maximise asset 2016年4月23日 — As in the case of the main dump hopper, many crusher chutes have electric heating elements to prevent the oil sands from sticking Although crusher capacities can vary between the operators, most crushers have a nominal (steadystate) capacity of between 8,000 to 10,000 tonnes per hour The largest crushers used in the oil sands OPPDry: Materials Handling Facilities Oil Sands Magazine

Noise and Vibration Control in Crusher Plant Activities to Enhance

2019年4月8日 — Six crusher plant sites were selected based on their varying production capacity for the study Accordingly, selected sites were visited to carry out area noise and wholebody vibration surveysREXLINE™ – Laminated Wear Blocks are unique wear resistant materials in that they combine very high wear resistant qualities of white iron (ASTM A532 15/3CrMo, 700BHN – 63HRc) with a weldable high impact toughness mild steel through a metallurgical bond to create a product that has a exceptional resistance to impact and abrasion NiHard Rexline™ Engineering Cco Nihard Wear Liners RexLine